Otomasyon ve AR destekli işgücü, üretim sürecini önemli ölçüde hızlandırırken aynı ilacın büyük miktarlarda üretimini mümkün kılarken, 3D baskı, ilaç firmalarının daha etkili doz formatlarında ilaç oluşturmasına ve düşük hacimli üretimin kişiselleştirilmiş ile birleşmesine olanak sağlar.

Fikir, düşündüğünüz kadar uzak değil. 2016 yılında FDA , 3D yazıcılar tarafından üretilen Spritam adlı epilepsi ilacını onayladı . Toz haline getirilmiş ilaç katmanını, ortalama haplardan daha hızlı eritmek için katman tarafından yazdırır. Howard Hughes Tıp Enstitüsü’yle çalışan bilim adamları, bir dizi kimyasal yapı taşını kullanarak küçük bir molekülün 14 farklı sınıfını sentezleyebilen yeni bir 3D yazıcı geliştirdiler .

Robotics, A.I. and Blockchain Redesign The Pharma Supply Chain

Exoskeletons will aid pharma factory workers. 3D printing will allow pharmacies to produce drugs on the spot. Blockchain technologies will help fight counterfeit drugs. These are just bits and pieces, but the entire process of the pharmaceutical supply chain will be affected by disruptive technologies. Let me show you a comprehensive overview how innovations will make it more efficient, faster and cheaper than ever before.

Robi, the dispenser robot in the room

“We call it Robi”, told me the smiling pharmacist when I looked in awe at the robotic dispenser pacing up and down in a small glass-fronted drug storage room. “Robi” is a nickname for Robert in Hungarian as well as a short, cute label for a robot. In its simplicity, I guess it fits the quiet, busy bee selecting the ordered medication, placing it in the right delivery box and storing the incoming new medication as requested.

When I went to the nearest pharmacy for some painkillers and asked the pharmacist lady behind the counter about the robot and why they removed the video displaying its activities, I didn’t expect an immediate personal encounter. But to my greatest surprise, she readily guided me to the storage room of the extremely busy facility in downtown Budapest to show me how the robot works. She told me, “lots of people ask about the dispenser robot, an old lady once only visited us to see it”.

The pharmacist ladies were visibly content with Robi’s work, they said it spares them two hours of medication stacking and distribution every single day. “And it only makes mistakes if I make one. Or when there are too many requests at the same time. It cannot handle multitasking. Yet”, explained one of them “feeding” Robi with new boxes of medication.

The pharmacists added that there are already a handful of pharmacies in Budapest “employing” dispenser robots, mostly the busiest facilities, sometimes with 24/7 service. They reduce the time for monotonous tasks and shorten the waiting time.

Diverse and diversified instead of linear supply chains

The latter, namely time, as well as efficiency, are key in the operation of the pharmaceutical supply chain. Its main objective is to deliver the right medication to the person in need as fast as possible – to aid the healing process in the best way possible. While the drug designing, manufacturing, and distribution supply chains have been changing constantly due to new technologies, the scope and quality of the recent transformation are much more profound.

First and foremost, these supply chains always represented a linear, one-way process: from the drug producer to the consumer. As technologies are integrating the patient more and more into the entire pharmaceutical industry – not as an end-user, but as an active shaper of outcomes, supply chains transform into two-way streets. Secondly, these networks have grown immensely in scope and complexity due to globalization, new technologies and the advancement of transportation. Thirdly, personalization and targeted treatments will result in the fragmentation and diversification of these networks, while fourthly, disruption will allow smaller companies with relatively few experiences to connect to the market. Moreover, there is a real chance for the home of the patient to also become part of the supply chain – due to 3D printing or artificial intelligence.

Of course, each technology will impact a different part of the pharmaceutical supply chain and to a different degree, so it is worth looking at them separately and in more detail.

Artificial Intelligence will design drugs in a flash

The incredibly fast pace of the development of Artificial Narrow Intelligence (ANI) already has an impact on medical imaging and radiology, but it has the potential for inducing a much more comprehensive transformation in healthcare. Regarding pharmaceutical supply chains, A.I. solutions could fundamentally alter the traditional process of designing drugs. They could significantly shorten the drug production circle and help out pharma in finding new drugs without burdening clinical trials and accumulating costs.

The traditional drug discovery method is basically a “trial and error” process with which it takes about 12 years and $2.9 billion to bring a new efficient drug on the market. Moreover, “error” here is huge as only very few experimental drugs ever see the medicine cabinet. On the other hand, smart algorithms using the power of ANI teach themselves complex biochemical principles and the factors that are ultimately the most predictive when it comes to the effectiveness of a drug. This way, they could analyze hundreds of millions of small molecules and potential interactions, be that linear or non-linear, almost at the same time. Tech giants, as well as plenty of start-ups in the US, Europe or China, are building artificial intelligence solutions to design personalized drugs and treatments faster than any traditional healthcare service.

Ebola, Atomwise and the race against the clock

San Francisco-based Atomwise uses supercomputers that root out therapies from a database of molecular structures. In 2016, Atomwise launched a virtual search in collaboration with IBM for safe, existing medicines that could be redesigned to treat the Ebola virus. They found two drugs predicted by the company’s A.I. technology which may significantly reduce Ebola infectivity. This analysis, which typically would have taken months or years, was completed in less than one day. In the context of another project, the startup studied 8.2 million small molecules to find potential cures for multiple sclerosis in a matter of days. The company is also cooperating with Dalhousie University in Canada to search for a measles treatment.

Microsoft’s research machine-learning project, dubbed Hanover and Budapest-based Turbine aim for something similar. They design smart algorithms able to sift through millions of documents and help predict which drugs in which combinations are the most effective. Boston-based biopharma group, Berg Health, let an artificial intelligence suggest a way of switching a cancerous cell back to a healthy one. It led to their first drug, named BPM31510, which tries to reverse the Warburg effect – the phenomenon in which cancerous cells change their energy supply. Data from 85 patients showed signs the approach could kill tumors. Palo Alto-based TwoXAR, founded in 2014, has been developing the DUMATM Drug Discovery platform able to evaluate large public and proprietary datasets to identify and rank high probability drug-disease matches in minutes rather than years.

Robotics and augmented reality will support drug manufacturing

Regarding pharmaceutical manufacturing, the magic word is robotics. With its need for speed, repeatability, and verification, it is ideally suited to benefit from robot automation. Manual labor is placed at a disadvantage when it comes to robots’ speed, consistency or cost-efficiency. Not only does the robot perform its tasks exactly as it is told to, everything it does can be thoroughly documented. Global robotics company, Denso Robotics, for example, offers the three most commonly used types of robots, cartesian, SCARA and articulated robots for different tasks in pharmaceutical manufacturing.

In the same way, as Robi’s example showed, robotics could have a big impact on pharmaceutical distribution chains, too. Robotic medical dispenser systems, medication management solutions such as the PharmASSIST ROBOTx help any given facility “right-size” its system for its volume. It is also an emerging best practice that these robots are designed with robust data mining capabilities, so pharmacies can gain valuable insights about their traffic and efficiency all the time.

Although robotics might replace the most monotonous and repetitive tasks of drug production and distribution, manual labor will continuously be used for more complex assignments requiring creativity and problem-solving skills. Digital technologies could give a helping hand here, too. For example, laborers could learn the trick of the trade faster and more efficiently through augmented reality. Moreover, their training would also not require extra workforce, so colleagues currently assigned with the coaching of newcomers might get different tasks. In another scenario, exoskeletons could aid workers to lift heavy loads and support them in enduring long hours of standing or other uncomfortable positions.

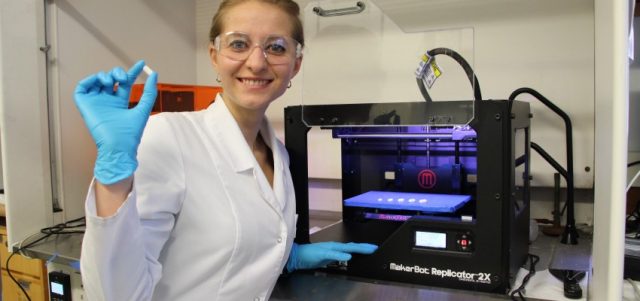

Alternative routes for production: 3D printing drugs in pharmacies

While automation and AR-supported workforce considerably speed up the process of manufacturing and enables the production of large quantities of the same medication, 3D printing would allow pharma companies to create drugs in more effective dose formats, and enable low-volume production coupled with personalized medicine.

The idea is not that far-fetched as you think. In 2016, the FDA just approved an epilepsy drug called Spritam that is made by 3D printers. It prints out the powdered drug layer by layer to make it dissolve faster than average pills. Scientists working with the Howard Hughes Medical Institute have developed a new 3D printerthat can synthesize 14 different classes of a small molecule using a set of chemical building blocks.

UK-based FabRx is already experimenting extensively with the technology, and they told The Medical Futurist that they plan to place the first printers in hospitals for the first in situ trials in less than 5 years. They believe the technology will be available everywhere in 5-10 years. However, the FabRx team was cautious about the potential of the GP e-mailing the drug prescription and the patient 3D printing it at home.

Blockchain securing distribution chains

Regarding drug distribution chains, the network where medication gets from pharmaceutical companies through distributors, hospitals, and pharmacies to the patient, the most important challenge is ensuring the safety and security of the products themselves. The issue of counterfeit medicines, as the dark side of networked markets and globalization, has become increasingly pressing, both in terms of the economic cost of this global black market and the risk to human life that comes from taking counterfeit drugs. In many developing countries in Asia, Africa, and South America, counterfeit drugs comprise between 10 percent and 30 percent of the total medicines on sale. That should definitely be changed, and the technology to help is the same that secures crypto-currencies at the moment: blockchain.

The technology offers security through transparency. It might work as follows: barcode-tagged drugs could be scanned and entered into secure digital blocks whenever they change hands. This ongoing real-time record could be viewed anytime by authorized parties and even patients at the far end of the supply chain. This would make it much more difficult for criminal networks to sell their counterfeit drugs on the market.

However, the advantages of blockchain for pharma do not stop there. Drug developers running clinical trials might be able to share clinical data and medical samples more securely and simply, while in healthcare, vaccine registries could be more easily set up and relied upon. And while blockchain underpins the digital currencies demanded in ransomware attacks, the technology could also play a role in securing sensitive industry data from malicious attack.

Overall, pharma should embrace digital health technologies or small companies coming from a garage might beat them at speed, patient centricity, and cost (the triad of success in the digital age).